Style LPD Y Strainer

Strainers

The Utah Water Research Laboratory uses the LPD Y-Strainer to remove particles in Logan River water used for testing mechanical flow measurement devices or mechanical flow control devices. Re-engineered, re-designed low pressure drop LPD Y-Strainer/Filter provides significant energy-savings The new…

Product Description

Product Highlights

Additional Resources

Submittals

Product Description

Re-engineered, re-designed low pressure drop LPD Y-Strainer/Filter provides significant energy-savings

The new Metraflex LPD Y-Strainer/Filter provides significant energy savings over the old Y-strainer. Metraflex has re-engineered the 110-year-old strainer and given it a leaner interior with fewer obstructions. The result is significantly lower pressure drops resulting in energy-savings so significant the LPD Y-strainer can pay for itself in months. View Utah Water Research Laboratory study.

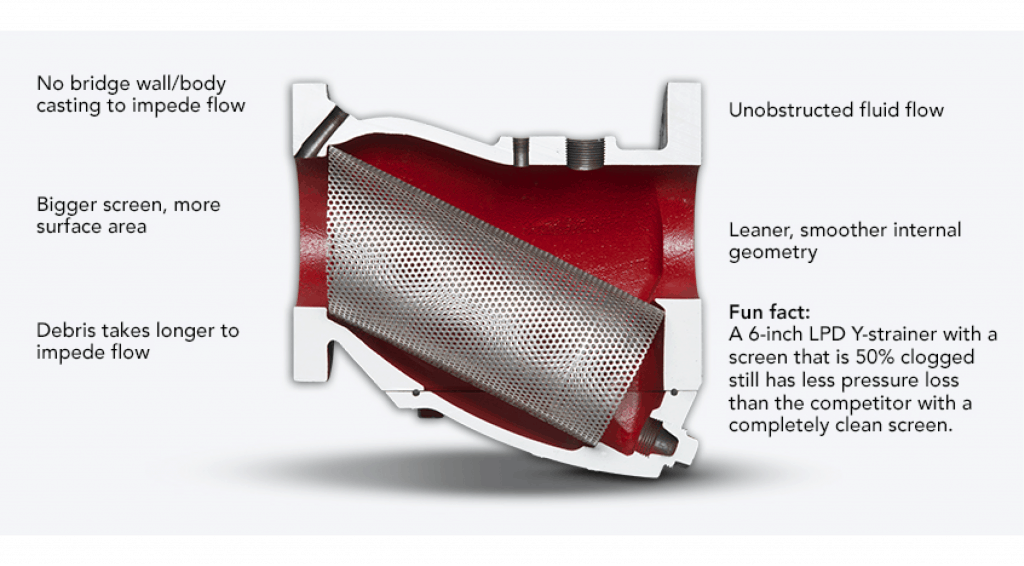

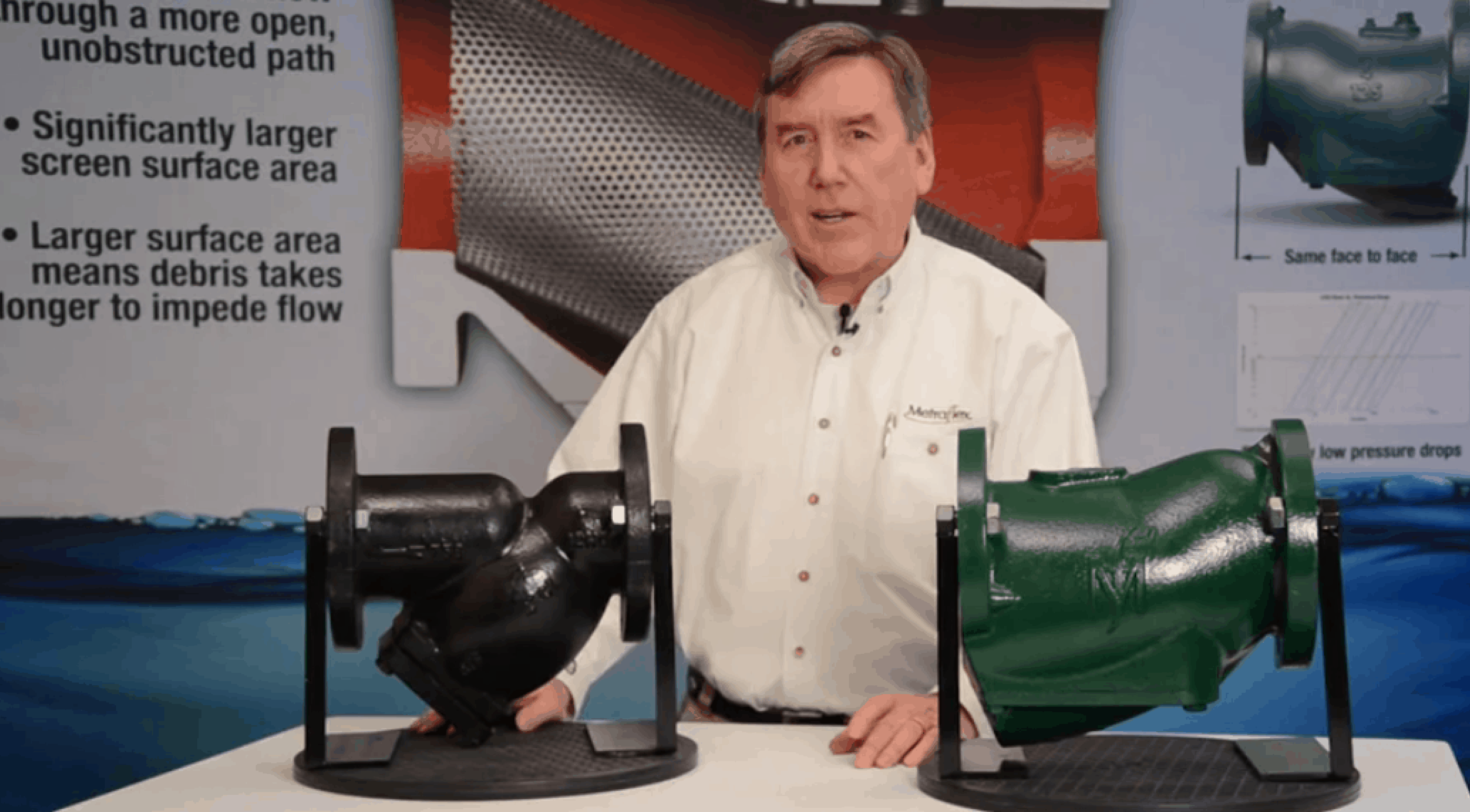

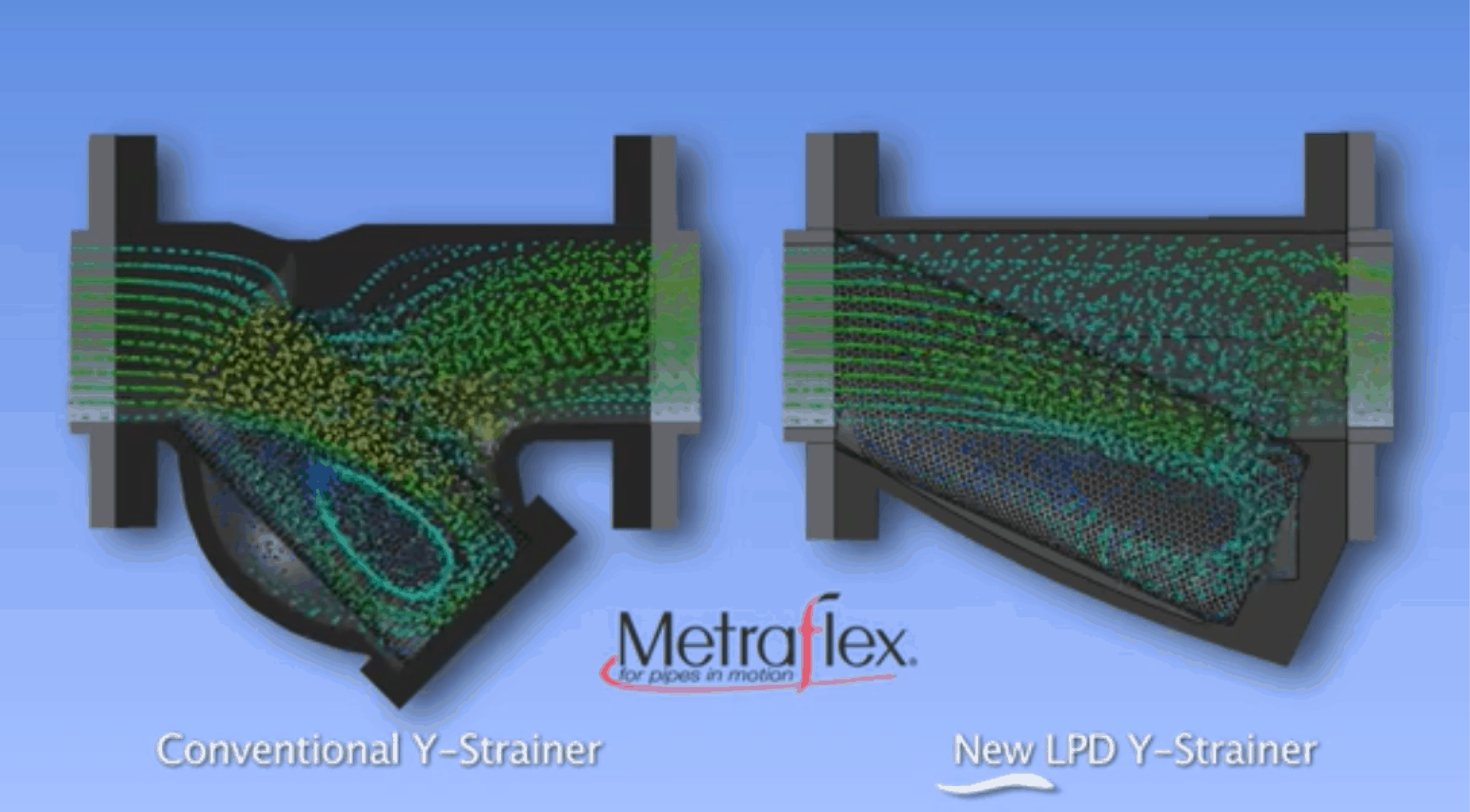

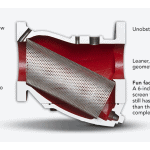

Lower pressure drops than traditional, old Y-strainers

Metraflex has removed the bridge wall/body casting structure that has traditionally diverted flow into the screen as it enters the strainer. Now flow takes a much straighter line from intake to discharge. Other internal structural improvements also help create a more open internal geometry, allowing for smoother flow throughout the strainer. The result is significantly lower pressure drops.

LPD Y strainer screen

You have the option to open the plug and drain the strainer, or easily access the screen by removing the plate.

The new LPD Y-strainer internal design also accommodates a significantly larger screen, up to 30% larger. This larger screen has more holes allowing smoother fluid flow. In addition, as debris collects, the same amount of debris trapped by both the new LPD Y-strainer screen and a traditional, old Y-strainer screen covers a significantly smaller percentage of the new LPD Y-strainer screen. This contributes to lower pressure loss. It also takes longer for debris to collect and significantly impact strainer performance.

Compare a 6-inch LPD Y-strainer to the traditional 6-inch Y-strainer

As an example, we compared a 6-inch LPD Y-strainer, with 50% of the screen clogged with debris, to a competitors completely clean 6-inch Y-strainer. The partially clogged LPD Y-strainer still has a lower pressure loss than the completely clean traditional Y strainer! View the pressure loss charts.

Metraflex has created a Y-strainer energy-savings calculator. You can use your real-world numbers to calculate the energy-savings you can expect using the new LPD Y-strainer.

The LPD Strainer® contributes toward satisfying EA Prerequisite: Minimum Energy Performance and MR Credit: Building Product Disclosure and Optimization – Material Ingredients under LEED®.

LEED® is the preeminent program for the design, construction, maintenance and operations of high-performance green buildings. Learn more at usgbc.org/LEED.

LEED®, and its related logo, is a trademark owned by the U.S. Green Building Council®

Product Highlights

- 30% larger screen size

- Hundreds of dollars in energy-savings yearly

- Streamlined design means straight, smooth flow

- Maximizes NPSH

- 2 thru 16 inch, 125#

- More efficient pump performance

Additional Resources

LPD Y Strainer Energy Savings Calculator

BIM / REVIT

View DrawingsWhite Paper

A Comparison of Traditional Y-Strainers and Basket Strainers to the LPD Strainer

Download NowSubmittals

LPD Y-Strainer Data Table

| METRAFLEX PART NO. | PIPE SIZE | WOG PRESSURE / TEMP | STEAM* PRESSURE / TEMP | WOG SCREEN | STEAM SCREEN | SIZE OF BLOWOFF (NPT) | BODY MATERIAL | SCREEN MATERIAL | WEIGHT LBS | BIM/REVIT | SUBMITTAL |

|---|---|---|---|---|---|---|---|---|---|---|---|

| LPD0200 | 2″ | 175 PSIG at 150 Deg F | 125 PSIG at 350 Deg F* | .045 Perf | .045 Perf | 1/2″ | ASTM A126B CI | 304 SS | 20 | Revit/CAD | Submittal |

| LPD0250 | 2 1/2″ | 175 PSIG at 150 Deg F | 125 PSIG at 350 Deg F* | .045 Perf | .045 Perf | 1″ | ASTM A126B CI | 304 SS | 30 | Revit/CAD | |

| LPD0300 | 3″ | 175 PSIG at 150 Deg F | 125 PSIG at 350 Deg F* | .045 Perf | .045 Perf | 1″ | ASTM A126B CI | 304 SS | 50 | Revit/CAD | |

| LPD0400 | 4″ | 175 PSIG at 150 Deg F | 125 PSIG at 350 Deg F* | .125 Perf | .045 Perf | 1-1/4″ | ASTM A126B CI | 304 SS | 75 | Revit/CAD | |

| LPD0500 | 5″ | 175 PSIG at 150 Deg F | 125 PSIG at 350 Deg F* | .125 Perf | .045 Perf | 1-1/4″ | ASTM A126B CI | 304 SS | 115 | Revit/CAD | |

| LPD0600 | 6″ | 175 PSIG at 150 Deg F | 125 PSIG at 350 Deg F* | .125 Perf | .045 Perf | 1-1/2″ | ASTM A126B CI | 304 SS | 154 | Revit/CAD | |

| LPD0800 | 8″ | 175 PSIG at 150 Deg F | 125 PSIG at 350 Deg F* | .125 Perf | .062 Perf | 1-1/2″ | ASTM A126B CI | 304 SS | 273 | Revit/CAD | |

| LPD1000 | 10″ | 175 PSIG at 150 Deg F | 125 PSIG at 350 Deg F* | .125 Perf | .062 Perf | 2″ | ASTM A126B CI | 304 SS | 464 | Revit/CAD | |

| LPD1200 | 12″ | 175 PSIG at 150 Deg F | 125 PSIG at 350 Deg F* | .125 Perf | .062 Perf | 2″ | ASTM A126B CI | 304 SS | 565 | ||

| LPD1400 | 14″ | 175 PSIG at 150 Deg F | 125 PSIG at 350 Deg F* | .125 Perf | .062 Perf | 2″ | ASTM A126B CI | 304 SS | 900 | ||

| LPD1600 | 16″ | 175 PSIG at 150 Deg F | 125 PSIG at 350 Deg F* | .125 Perf | .062 Perf | 2″ | ASTM A126B CI | 304 SS | 1300 |

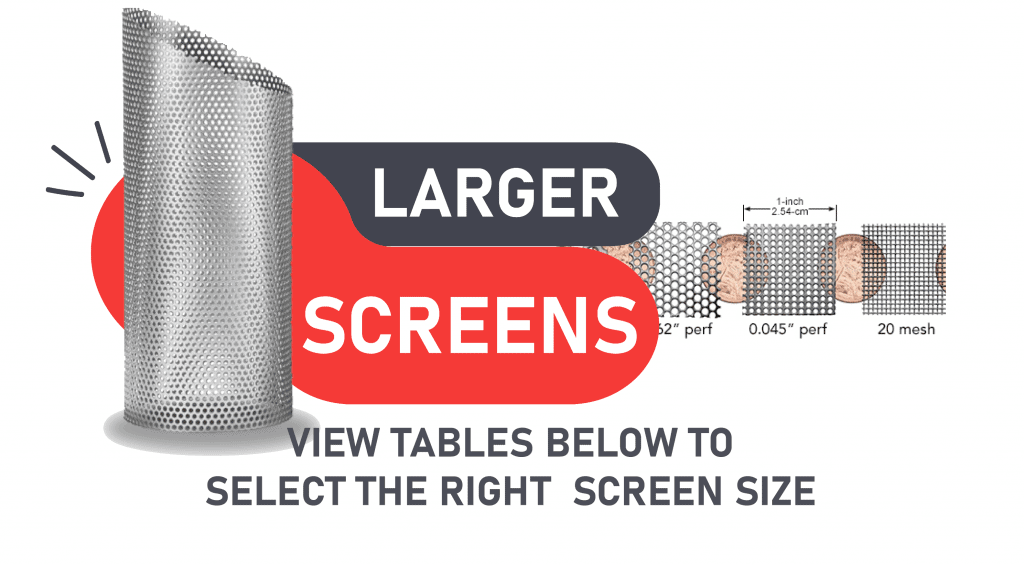

How to Select the Right Screen

Pictured above, against a US penny for scale, are the most common screen options requested. Check with the other system components for maximum particle size and spec a screen slightly smaller. Too often we see a tendency to select holes smaller than needed. This increases pressure drop and needlessly wastes energy. Without knowing the maximum permitted particle size, we have suggested standards for water and steam applications.

Water Service: Although many options are available, the industry has standardized on a few hole diameters. Metraflex is no exception. For 2 inch thru 3 inch, water service, we provide 0.045” perforated stainless steel screens. 4 inch thru 12 inch, water service, our standard recommended screen is 0.125” perforated stainless steel.

Steam Service: Steam service is different in that most steam components are not as tolerant of debris as are water components. Steam traps, heat exchangers, control valves need more protection. For steam our standard perforation is 0.045” to 6 inch diameter and 0.62” for 8 inch and larger strainers.

Mesh screens: Many times mesh is used to line perforated screens for system startups. After a system is run for a few days, the strainer is opened, the mesh lining is removed and the perforated screen is reinstalled. Be sure to note that during ordering that the mesh lining is for startup. It will be attached in such a way that it can easily be removed without damaging the permanent screen.

⚠ Please Note: Differential pressure, clogs and screen strength. As debris accumulates the differential pressure upstream of the screen and downstream cannot exceed 20psi. The screen itself cannot withstand the same pressures as the body. The LPD strainer is tapped with ports to readily accept differential pressure gauges. Adding gauges is always a good practice as well as protecting the screen from a catastrophic failure; your system will run much more efficiently knowing when blow downs are needed.