High/Low Temperature Seal

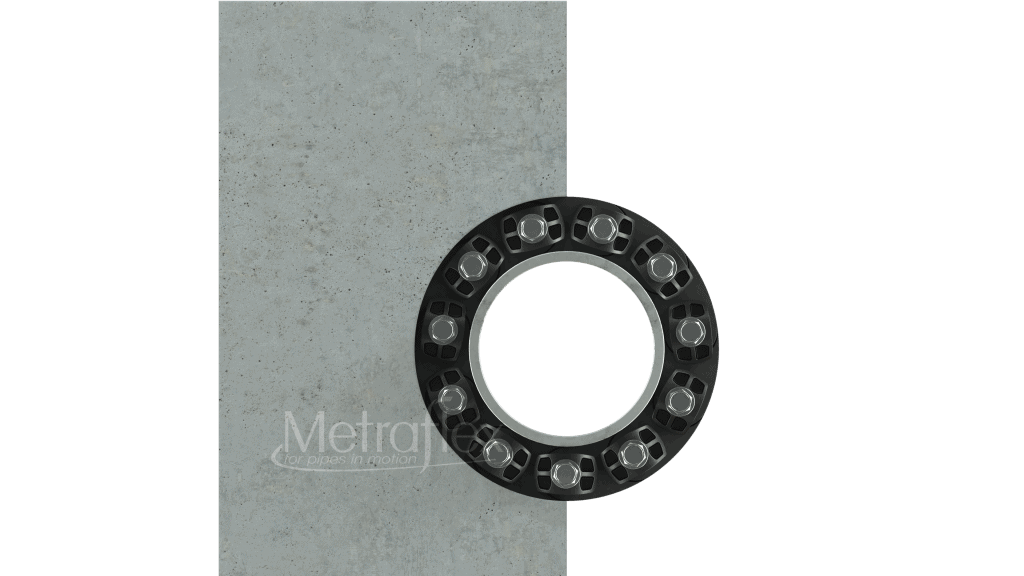

Wall Penetration Seals

Low durometer silicone seal withstands extreme temperatures. The MetraSeal silicone wall penetration seal for high and low temperatures will withstand extreme temperatures and still maintain a water-tight seal. With a working range from -40°F to 400°F, the MetraSeal low durometer…

Product Description

Product Highlights

Additional Resources

Submittals

Product Description

Low durometer silicone seal withstands extreme temperatures.

The MetraSeal silicone wall penetration seal for high and low temperatures will withstand extreme temperatures and still maintain a water-tight seal. With a working range from -40°F to 400°F, the MetraSeal low durometer temperature seal is ideal for indoor/outdoor applications, steam, high temperature piping systems, refrigeration and where environmental factors can adversely impact traditional seals.

- Install around any round pipe.

- Install in any weather.

- Install inside or outside.

- Faster installations.

- No drying or curing time.

- A cleaner, more positive installation.

The Metraflex MetraSeal quickly fills the space around any round pipe, including concrete, steel, plastic, cast iron, copper, telecommunications cable and electric, with a snug, permanent seal. And it does it up to 75% faster than when using messy, weather-sensitive lead-oakum, mastics or casing boots. No drying or curing time is needed.

Rated at 20 psig, it is engineered as a permanent seal, resisting aging, water, ozone and sunlight for up to 25 years. The MetraSeal seals out groundwater in subgrade exterior walls, and absorbs noise and vibration. It is also ideal for filling gaps in interior walls and floors, keeping unwanted noise and fumes from invading office space. It has the added benefit of diminishing annoying liquid and turbulence noise.

Unlike other seals, MetraSeal can be installed in even the coldest weather, helping to keep projects on schedule. It can compensate for piping misalignment, and protects against galvanic corrosion by separating piping from metal casings.

Product Highlights

- Rated -40ºF to 400ºF

- Reusable, permanent, water stop

- Rated at 20 psi

- Mechanical, interlocking links

- For steam piping penetrating walls/floors

Additional Resources

MetraSeal Seal Creator

Submittals

Standard Weight Steel Pipe, PVC and CPVC Pipe

| Nominal Pipe Size | Actual Pipe O.D. | Standard Weight Steel Pipe Sleeve | Core Drill or Cast Hole* | |||||

|---|---|---|---|---|---|---|---|---|

| Sleeve Nominal Pipe Size | Sleeve Actual I.D. | MetraSeal Model No. | No. of Links Needed | Hole I.D. | MetraSeal Model No. | No. of Links Needed | ||

| 1/2″ | 0.840″ | 2″ | 2.067″ | MS 200 | 4 | 2.000″ | MS 200 | 4 |

| 3/4″ | 1.050″ | 2-1/2″ | 2.469″ | MS 275 | 6 | 2.500″ | MS 275 | 6 |

| 1″ | 1.315″ | 2-1/2″ | 2.469″ | MS 200 | 5 | 3.000″ | MS 315 | 4 |

| 1-1/4″ | 1.660″ | 3″ | 3.068″ | MS 275 | 8 | 3.000″ | MS 275 | 8 |

| 1-1/2″ | 1.900″ | 3″ | 3.068″ | MS 200 | 7 | 3.500″ | MS 300 | 5 |

| 2″ | 2.375″ | 3-1/2″ | 3.548″ | MS 200 | 8 | 4.000″ | MS 300 | 6 |

| 2-1/2″ | 2.875″ | 4″ | 4.026″ | MS 200 | 9 | 4.000″ | MS 200 | 9 |

| 3″ | 3.500″ | 5″ | 5.047″ | MS 300 | 8 | 5.000″ | MS 300 | 8 |

| 3-1/2″ | 4.000″ | 6″ | 6.065″ | MS 315 | 10 | 6.000″ | MS 315 | 10 |

| 4″ | 4.500″ | 6″ | 6.065″ | MS 300 | 10 | 6.000″ | MS 300 | 10 |

| 5″ | 5.563″ | 8″ | 7.981″ | MS 340 | 13 | 8.000″ | MS 340 | 13 |

| 6″ | 6.625″ | 10″ | 10.020″ | MS 475 | 10 | 10.000″ | MS 475 | 10 |

| 8″ | 8.625″ | 12″ | 12.000″ | MS 475 | 12 | 12.000″ | MS 475 | 12 |

| 10″ | 10.750″ | 14″ | 13.250″ | MS 425 | 10 | 14.000″ | MS 475 | 14 |

| 12″ | 12.750″ | 16″ | 15.250″ | MS 425 | 12 | 16.000″ | MS 475 | 17 |

| 14″ | 14.000″ | 18″ | 17.250″ | MS 475 | 18 | 18.000″ | MS 575 | 16 |

| 16″ | 16.000″ | 20″ | 19.250″ | MS 475 | 21 | 20.000″ | MS 575 | 18 |

| 18″ | 18.000″ | 22″ | 21.250″ | MS 475 | 23 | 22.000″ | MS 575 | 20 |

| 20″ | 20.000″ | 24″ | 23.250″ | MS 475 | 25 | 24.000″ | MS 575 | 22 |

| 22″ | 22.000″ | 26″ | 25.250″ | MS 475 | 28 | 26.000″ | MS 575 | 24 |

| 24″ | 24.000″ | 28″ | 27.250″ | MS 475 | 30 | 28.000″ | MS 575 | 26 |

| 26″ | 26.000″ | 30″ | 29.250″ | MS 475 | 33 | 30.000″ | MS 575 | 28 |

| 28″ | 28.000″ | 32″ | 31.250″ | MS 475 | 35 | 32.000″ | MS 575 | 30 |

| 30″ | 30.000″ | 34″ | 33.250″ | MS 475 | 37 | 34.000″ | MS 575 | 32 |

| 32″ | 32.000″ | 36″ | 35.250″ | MS 475 | 40 | 36.000″ | MS 575 | 34 |

| 34″ | 34.000″ | 40″ | 39.250″ | MS 500 | 29 | 38.000″ | MS 575 | 36 |

| 36″ | 36.000″ | 42″ | 41.250″ | MS 500 | 31 | 40.000″ | MS 575 | 38 |

| 42″ | 42.000″ | 48″ | 47.250″ | MS 500 | 36 | 46.000″ | MS 575 | 44 |

| 48″ | 48.000″ | 54″ | 53.250″ | MS 500 | 41 | 52.000″ | MS 575 | 50 |

*Min. recommended sleeve length or wall thickness is 4″ for MetraSeal model 325 and smaller and 6″ for models 400 and larger.

PVC sleeves are sch. 40, and have a different I.D. at 12″ and above.

Copper Tubing

| Nominal Pipe Size | Actual Pipe O.D. | Standard Weight Steel Pipe Sleeve | Core Drill or Cast Hole* | |||||

|---|---|---|---|---|---|---|---|---|

| Sleeve Nominal Pipe Size | Sleeve Actual I.D. | MetraSeal Model No. | No. of Links Needed | Hole I.D. | MetraSeal Model No. | No. of Links Needed | ||

| 1/2″ | 0.625″ | 2″ | 2.067″ | MS 275 | 4 | 2.000″ | MS 275 | 4 |

| 3/4″ | 0.875″ | 2″ | 2.067″ | MS 200 | 4 | 2.000″ | MS 200 | 4 |

| 1″ | 1.125″ | 2-1/2″ | 2.469″ | MS 275 | 6 | 3.000″ | MS 315 | 4 |

| 1-1/4″ | 1.375″ | 2-1/2″ | 2.469″ | MS 200 | 5 | 3.000″ | MS 300 | 4 |

| 1-1/2″ | 1.625″ | 3″ | 3.068″ | MS 275 | 8 | 3.000″ | MS 275 | 8 |

| 2″ | 2.125″ | 3-1/2″ | 3.548″ | MS 300 | 5 | 3.500″ | MS 275 | 9 |

| 2-1/2″ | 2.625″ | 4″ | 4.026″ | MS 275 | 11 | 4.000″ | MS 275 | 11 |

| 3″ | 3.125″ | 5″ | 5.047″ | MS 315 | 8 | 5.000″ | MS 315 | 8 |

| 4″ | 4.125″ | 6″ | 6.065″ | MS 315 | 10 | 6.000″ | MS 315 | 10 |

| 6″ | 6.125″ | 8″ | 7.981″ | MS 315 | 15 | 8.000″ | MS 315 | 15 |

| 8″ | 8.125″ | 10″ | 10.020″ | MS 325 | 9 | 12.000″ | MS 575 | 10 |

| 10″ | 10.125″ | 14″ | 13.250″ | MS 410 | 14 | 14.000″ | MS 575 | 12 |

| 12″ | 12.125″ | 16″ | 15.250″ | MS 410 | 16 | 16.000″ | MS 575 | 14 |

*Min. recommended sleeve length or wall thickness is 4″ for MetraSeal model 325 and smaller and 6″ for models 400 and larger.

PVC sleeves are sch. 40, and have a different I.D. at 12″ and above.

Electrical Metallic Tubing (Thin Wall)

| Nominal Pipe Size | Actual Pipe O.D. | Standard Weight Steel Pipe Sleeve | Core Drill or Cast Hole* | |||||

|---|---|---|---|---|---|---|---|---|

| Sleeve Nominal Pipe Size | Sleeve Actual I.D. | MetraSeal Model No. | No. of Links Needed | Hole I.D. | MetraSeal Model No. | No. of Links Needed | ||

| 1/2″ | 0.706″ | 2″ | 2.067″ | MS 275 | 4 | 2.000″ | MS 275 | 4 |

| 3/4″ | 0.922″ | 2″ | 2.067″ | MS 200 | 4 | 2.000″ | MS 200 | 4 |

| 1″ | 1.163″ | 2-1/2″ | 2.469″ | MS 275 | 6 | 3.000″ | MS 315 | 4 |

| 1-1/4″ | 1.510″ | 3″ | 3.068″ | MS 275 | 7 | 3.000″ | MS 275 | 7 |

| 1-1/2″ | 1.740″ | 3-1/2″ | 3.548″ | MS 315 | 5 | 3.500″ | MS 315 | 5 |

| 2″ | 2.197″ | 3-1/2″ | 3.548″ | MS 275 | 10 | 4.000″ | MS 315 | 6 |

| 2-1/2″ | 2.875″ | 4″ | 4.026″ | MS 200 | 9 | 4.000″ | MS 200 | 9 |

| 3″ | 3.500″ | 5″ | 5.047″ | MS 300 | 8 | 5.000″ | MS 300 | 8 |

| 4″ | 4.500″ | 6″ | 6.065″ | MS 300 | 10 | 6.000″ | MS 300 | 10 |

*Min. recommended sleeve length or wall thickness is 4″ for MetraSeal model 325 and smaller and 6″ for models 400 and larger.

PVC sleeves are sch. 40, and have a different I.D. at 12″ and above.

Intermediate Metal Conduit (IMC)

| Nominal Pipe Size | Actual Pipe O.D. | Standard Weight Steel or PVC Pipe Sleeve* | Cast or Core Bit Drileld Hole* | |||||

|---|---|---|---|---|---|---|---|---|

| Sleeve Nominal Pipe Size | Sleeve Actual I.D. | Metraseal Model No. | No. of Links Needed | Hole I.D. | Metraseal Model No. | No. of Links Required | ||

| 1/2″ | .815″ | 2″ | 2.067″ | MS 200 | 4 | 2.0″ | MS 200 | 4 |

| 3/4″ | 1.029″ | 2″ | 2.067″ | MS 200 | 4 | 2.5″ | MS 275 | 6 |

| 1″ | 1.290″ | 2-1/2″ | 2.469″ | MS 275 | 6 | 3.0″ | MS 300 | 4 |

| 1-1/4″ | 1.638″ | 3-1/2″ | 3.548″ | MS 315 | 5 | 3.0″ | MS 275 | 7 |

| 1-1/2″ | 1.883″ | 3-1/2″ | 3.548″ | MS 300 | 5 | 3.5″ | MS 300 | 5 |

| 2″ | 2.360″ | 4″ | 4.026″ | MS 300 | 6 | 4.0″ | MS 300 | 6 |

| 2-1/2″ | 2.857″ | 4″ | 4.026″ | MS 200 | 9 | 4.0″ | MS 200 | 9 |

| 3″ | 3.476″ | 5″ | 5.047″ | MS 360 | 7 | 5.0″ | MS 300 | 8 |

| 3-1/2″ | 3.971″ | 6″ | 6.065″ | MS 340 | 9 | 6.0″ | MS 325 | 5 |

| 4″ | 4.466″ | 6″ | 6.065″ | MS 300 | 10 | 6.0″ | MS 300 | 10 |

*Minimum recommended sleeve length or wall thickness is 4″ for MetraSeal model 325 and smaller and 6″ for models 400 and larger.

Rigid Steel Conduit (RSC)

| Nominal Pipe Size | Actual Pipe O.D. | Standard Weight Steel or PVC Pipe Sleeve* | Cast or Core Bit Drilled Hole* | |||||

|---|---|---|---|---|---|---|---|---|

| Sleeve Nominal Pipe Size | Sleeve Actual I.D. | Metraseal Model No. | No. of Links Required | Hole I.D. | Metraseal Model No. | No. of Links Required | ||

| 1/2″ | .840″ | 2″ | 2.067″ | MS 200 | 4 | 2.0″ | MS 200 | 4 |

| 3/4″ | 1.050″ | 2-1/2″ | 2.469″ | MS 275 | 6 | 2.5″ | MS 275 | 6 |

| 1″ | 1.315″ | 2-1/2″ | 2.469″ | MS 200 | 5 | 3.0″ | MS 300 | 4 |

| 1-1/4″ | 1.660″ | 3-1/2″ | 3.548″ | MS 315 | 5 | 3.0″ | MS 275 | 7 |

| 1-1/2″ | 1.900″ | 3-1/2″ | 3.548″ | MS 300 | 5 | 3.5″ | MS 300 | 5 |

| 2″ | 2.375″ | 4″ | 4.026″ | MS 300 | 6 | 4.0″ | MS 300 | 6 |

| 2-1/2″ | 2.875″ | 4″ | 4.026″ | MS 200 | 9 | 4.0″ | MS 200 | 9 |

| 3″ | 3.500″ | 5″ | 5.047″ | MS 300 | 8 | 5.0″ | MS 300 | 8 |

| 3-1/2″ | 4.000″ | 6″ | 6.065″ | MS 340 | 9 | 6.0″ | MS 325 | 5 |

| 4″ | 4.500″ | 6″ | 6.065″ | MS 300 | 10 | 6.0″ | MS 300 | 10 |

| 5″ | 5.563″ | 8″ | 7.981″ | MS 425 | 6 | 8.0″ | MS 425 | 6 |

| 6″ | 6.625″ | 8″ | 7.981″ | MS 300 | 15 | 10.0″ | MS 475 | 10 |

*Minimum recommended sleeve length or wall thickness is 4″ for MetraSeal model 325 and smaller and 6″ for models 400 and larger.

Ductile Iron Soil Pipe (AWWA Type)

| Nominal Pipe Size | Actual Pipe O.D. | Standard Weight Steel Pipe Sleeve | Core Drill or Cast Hole* | |||||

|---|---|---|---|---|---|---|---|---|

| Sleeve Nominal Pipe Size | Sleeve Actual I.D. | MetraSeal Model No. | No. of Links Needed | Hole I.D. | MetraSeal Model No. | No. of Links Needed | ||

| 2″ | 2.500″ | 3-1/2″ | 3.548″ | MS 200 | 8 | 4.000″ | MS 300 | 6 |

| 2-1/4″ | 2.750″ | 5″ | 5.047″ | MS 340 | 7 | 5.000″ | MS 340 | 7 |

| 3″ | 3.960″ | 6″ | 6.065″ | MS 315 | 10 | 6.000″ | MS 315 | 10 |

| 4″ | 4.800″ | 8″ | 7.981″ | MS 410 | 7 | 8.000″ | MS 410 | 7 |

| 6″ | 6.900″ | 10″ | 10.020″ | MS 410 | 10 | 10.000″ | MS 410 | 10 |

| 8″ | 9.050″ | 12″ | 12.000″ | MS 400 | 9 | 12.000″ | MS 400 | 9 |

| 10″ | 11.100″ | 14″ | 13.250″ | MS 340 | 24 | 14.000″ | MS 400 | 10 |

| 12″ | 13.200″ | 16″ | 15.250″ | MS 325 | 14 | 16.000″ | MS 360 | 21 |

| 14″ | 15.300″ | 18″ | 17.250″ | MS 325 | 16 | 18.000″ | MS 360 | 24 |

| 16″ | 17.400″ | 20″ | 19.250″ | MS 315 | 39 | 20.000″ | MS 360 | 27 |

| 18″ | 19.500″ | 24″ | 23.250″ | MS 475 | 25 | 24.000″ | MS 525 | 17 |

| 20″ | 21.600″ | 26″ | 25.250″ | MS 475 | 28 | 26.000″ | MS 525 | 19 |

| 24″ | 25.800″ | 30″ | 29.250″ | MS 475 | 32 | 28.000″ | MS 340 | 53 |

| 30″ | 32.000″ | 36″ | 35.250″ | MS 475 | 40 | 36.000″ | MS 575 | 34 |

| 36″ | 38.300″ | 42″ | 41.250″ | MS 400 | 34 | 42.000″ | MS 475 | 47 |

| 42″ | 44.500″ | 50″ | 49.250″ | MS 500 | 38 | 50.000″ | MS 500 | 38 |

| 48″ | 50.800″ | 54″ | 53.250″ | MS 425 | 45 | 56.000″ | MS 500 | 43 |

*Min. recommended sleeve length or wall thickness is 4″ for MetraSeal model 325 and smaller and 6″ for models 400 and larger.

PVC sleeves are sch. 40, and have a different I.D. at 12″ and above.

Cast Iron Soil Pipe (Extra Heavy)

| Nominal Pipe Size | Actual Pipe O.D. | Standard Weight Steel Pipe Sleeve | Core Drill or Cast Hole* | |||||

|---|---|---|---|---|---|---|---|---|

| Sleeve Nominal Pipe Size | Sleeve Actual I.D. | MetraSeal Model No. | No. of Links Needed | Hole I.D. | MetraSeal Model No. | No. of Links Needed | ||

| 2″ | 2.380″ | 3-1/2″ | 3.548″ | MS 200 | 8 | 4.000″ | MS 300 | 6 |

| 3″ | 3.500″ | 5″ | 5.047″ | MS 300 | 8 | 5.000″ | MS 300 | 8 |

| 4″ | 4.500″ | 6″ | 6.065″ | MS 300 | 10 | 6.000″ | MS 300 | 10 |

| 5″ | 5.500″ | 8″ | 7.981″ | MS 340 | 13 | 8.000″ | MS 340 | 13 |

| 6″ | 6.500″ | 10″ | 10.020″ | MS 475 | 9 | 10.000″ | MS 475 | 9 |

| 8″ | 8.620″ | 12″ | 12.000″ | MS 475 | 12 | 12.000″ | MS 475 | 12 |

| 10″ | 10.750″ | 14″ | 13.250″ | MS 425 | 10 | 14.000″ | MS 475 | 14 |

| 12″ | 12.750″ | 16″ | 15.250″ | MS 425 | 12 | 16.000″ | MS 475 | 17 |

| 15″ | 15.880″ | 20″ | 19.250″ | MS 475 | 21 | 18.000″ | MS 340 | 33 |

*Min. recommended sleeve length or wall thickness is 4″ for MetraSeal model 325 and smaller and 6″ for models 400 and larger.

PVC sleeves are sch. 40, and have a different I.D. at 12″ and above.

Cast Iron Soil Pipe (Service Weight)

| Nominal Pipe Size | Actual Pipe O.D. | Standard Weight Steel Pipe Sleeve | Core Drill or Cast Hole* | |||||

|---|---|---|---|---|---|---|---|---|

| Sleeve Nominal Pipe Size | Sleeve Actual I.D. | MetraSeal Model No. | No. of Links Needed | Hole I.D. | MetraSeal Model No. | No. of Links Needed | ||

| 2″ | 2.300″ | 4″ | 4.026″ | MS 315 | 6 | 4.000″ | MS 315 | 6 |

| 3″ | 3.300″ | 5″ | 5.047″ | MS 315 | 9 | 5.000″ | MS 315 | 8 |

| 4″ | 4.300″ | 6″ | 6.065″ | MS 315 | 11 | 6.000″ | MS 315 | 11 |

| 5″ | 5.300″ | 8″ | 7.981″ | MS 360 | 10 | 8.000″ | MS 360 | 10 |

| 6″ | 6.300″ | 8″ | 7.981″ | MS 315 | 15 | 8.000″ | MS 315 | 15 |

| 8″ | 8.380″ | 12″ | 12.000″ | MS 475 | 12 | 12.000″ | MS 475 | 12 |

| 10″ | 10.500″ | 14″ | 13.250″ | MS 360 | 17 | 14.000″ | MS 475 | 14 |

| 12″ | 12.500″ | 16″ | 15.250″ | MS 360 | 20 | 16.000″ | MS 475 | 17 |

| 15″ | 15.620″ | 20″ | 19.250″ | MS 475 | 20 | 18.000″ | MS 425 | 14 |

*Min. recommended sleeve length or wall thickness is 4″ for MetraSeal model 325 and smaller and 6″ for models 400 and larger.

PVC sleeves are sch. 40, and have a different I.D. at 12″ and above.