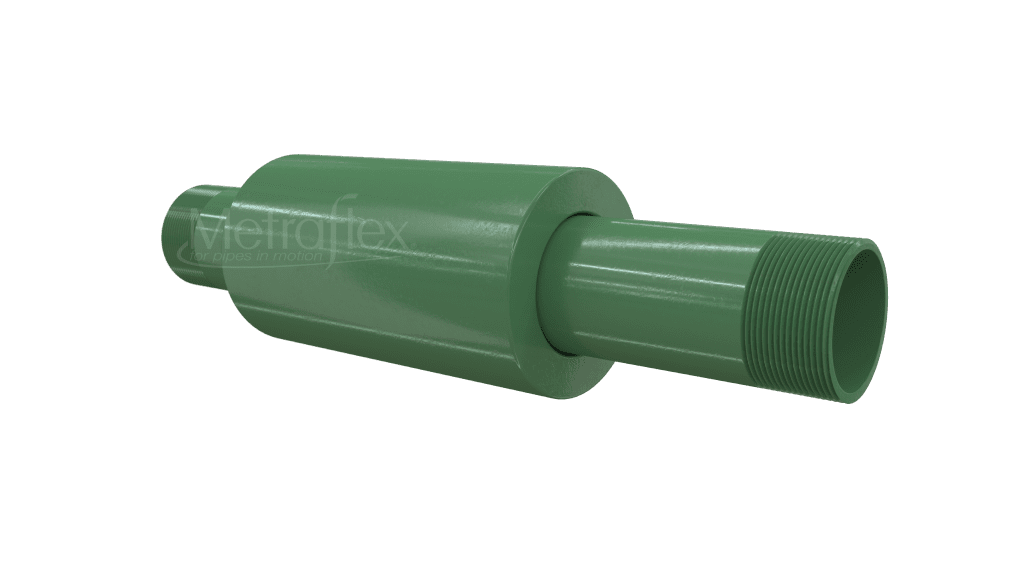

Model HP3 Compensator

Compensators

The HP3 is an externally pressurized expansion compensator that has several advantages over other in-line bellows joints. Since the pressure is on the outside of the bellows, more corrugations can be added to the design resulting in a joint capable…

Product Description

Product Highlights

Additional Resources

Submittals

Product Description

The HP3 is an externally pressurized expansion compensator that has several advantages over other in-line bellows joints. Since the pressure is on the outside of the bellows, more corrugations can be added to the design resulting in a joint capable of more movement. The design features pipe that acts as a liner and a casing that acts as a cover to protect the bellows from damage. An internal guide makes this a stable, rugged joint.

All in-line bellows expansion joints develop anchor loads and require guiding. Refer to the Expansion Joint Design Guide or consult Metraflex or your local representative for more information.

Product Highlights

- Conforms to MIL-DTL-17813H

- Maximum Working Temperature 500⁰ F

- Maximum Working Pressure 175 PSI

- Maximum Test Pressure 250 PSI at 70°F.

- Body Carbon Steel

- Bellows 2-Ply 304 Stainless Steel

- End Fittings

- 150# Carbon Steel Plate Flanges with 150 lb. drilling.

- Thread Ends (MPT with anti-torque protection)

- Weld Ends

Additional Resources

BIM / REVIT

View DrawingsSubmittals

HP3 - Carbon Steel Body, 304 Stainless Steel Bellows, Weld Ends

| PART NO. | Pipe Size | Pressure/Temp* | Compression | Extension | Effective Area (in2) |

Spring Rate (lbs/in) |

Weight | 3D Drawing |

|---|---|---|---|---|---|---|---|---|

| HPW30075 | .75″ | 175 PSIG at 500°F. | 3″ | 0.5″ | 1.5 | 58 | 4 | Revit/CAD |

| HPW30100 | 1″ | 175 PSIG at 500°F. | 3″ | 0.5″ | 2.1 | 63 | 6 | Revit/CAD |

| HPW30125 | 1.25″ | 175 PSIG at 500°F. | 3″ | 0.5″ | 3.3 | 52 | 6 | Revit/CAD |

| HPW30150 | 1.5″ | 175 PSIG at 500°F. | 3″ | 0.5″ | 4.3 | 82 | 8 | Revit/CAD |

| HPW30200 | 2″ | 175 PSIG at 500°F. | 3″ | 0.5″ | 6.3 | 117 | 12 | Revit/CAD |

| HPW30250 | 2.5″ | 175 PSIG at 500°F. | 3″ | 0.5″ | 8.8 | 132 | 16 | Revit/CAD |

| HPW30300 | 3″ | 175 PSIG at 500°F. | 3″ | 0.5″ | 13.1 | 161 | 21 | Revit/CAD |

| HPW30400 | 4″ | 175 PSIG at 500°F. | 3″ | 0.5″ | 20.8 | 341 | 28 | Revit/CAD |

*Joint temperature and pressure ratings depend on the gasket selected by others.

HP3 - Carbon Steel Body, 304 Stainless Steel Bellows, Thread Ends

| PART NO. | Pipe Size | Pressure/Temp* | Compression | Extension | Effective Area (in2) |

Spring Rate (lbs/in) |

Weight | 3D Drawing |

|---|---|---|---|---|---|---|---|---|

| HPT30075 | .75″ | 175 PSIG at 500°F. | 3″ | 0.5″ | 1.5 | 58 | 4 | Revit/CAD |

| HPT30100 | 1″ | 175 PSIG at 500°F. | 3″ | 0.5″ | 2.1 | 63 | 6 | Revit/CAD |

| HPT30125 | 1.25″ | 175 PSIG at 500°F. | 3″ | 0.5″ | 3.3 | 52 | 6 | Revit/CAD |

| HPT30150 | 1.5″ | 175 PSIG at 500°F. | 3″ | 0.5″ | 4.3 | 82 | 8 | Revit/CAD |

| HPT30200 | 2″ | 175 PSIG at 500°F. | 3″ | 0.5″ | 6.3 | 117 | 12 | Revit/CAD |

| HPT30250 | 2.5″ | 175 PSIG at 500°F. | 3″ | 0.5″ | 8.8 | 132 | 16 | Revit/CAD |

| HPT30300 | 3″ | 175 PSIG at 500°F. | 3″ | 0.5″ | 13.1 | 161 | 21 | Revit/CAD |

| HPT30400 | 4″ | 175 PSIG at 500°F. | 3″ | 0.5″ | 20.8 | 341 | 28 | Revit/CAD |

*Joint temperature and pressure ratings depend on the gasket selected by others.

HP3 - Carbon Steel Body, 304 Stainless Steel Bellows, Flanged Ends

| PART NO. | Pipe Size | Pressure/Temp* | Compression | Extension | Effective Area (in2) |

Spring Rate (lbs/in) |

Weight | 3D Drawing |

|---|---|---|---|---|---|---|---|---|

| HPF30075 | .75″ | 175 PSIG at 500°F. | 3″ | 0.5″ | 1.5 | 58 | 9 | Revit/CAD |

| HPF30100 | 1″ | 175 PSIG at 500°F. | 3″ | 0.5″ | 2.1 | 63 | 12 | Revit/CAD |

| HPF30125 | 1.25″ | 175 PSIG at 500°F. | 3″ | 0.5″ | 3.3 | 52 | 13 | Revit/CAD |

| HPF30150 | 1.5″ | 175 PSIG at 500°F. | 3″ | 0.5″ | 4.3 | 82 | 15 | Revit/CAD |

| HPF30200 | 2″ | 175 PSIG at 500°F. | 3″ | 0.5″ | 6.3 | 117 | 20 | Revit/CAD |

| HPF30250 | 2.5″ | 175 PSIG at 500°F. | 3″ | 0.5″ | 8.8 | 132 | 31 | Revit/CAD |

| HPF30300 | 3″ | 175 PSIG at 500°F. | 3″ | 0.5″ | 13.1 | 161 | 36 | Revit/CAD |

| HPF30400 | 4″ | 175 PSIG at 500°F. | 3″ | 0.5″ | 20.8 | 341 | 49 | Revit/CAD |

*Joint temperature and pressure ratings depend on the gasket selected by others.

HP3 - Carbon Steel Body, 304 Stainless Steel Bellows, Groove Ends

| PART NO. | Pipe Size | Pressure/Temp* | Compression | Extension | Effective Area (in2) |

Spring Rate (lbs/in) |

Weight |

|---|---|---|---|---|---|---|---|

| HPG30075 | .75″ | 175 PSIG at 500°F | 3″ | 0.5″ | 1.5 | 58 | 4 |

| HPG30100 | 1″ | 175 PSIG at 500°F | 3″ | 0.5″ | 2.1 | 63 | 6 |

| HPG30125 | 1.25″ | 175 PSIG at 500°F | 3″ | 0.5″ | 3.3 | 52 | 6 |

| HPG30150 | 1.5″ | 175 PSIG at 500°F | 3″ | 0.5″ | 4.3 | 82 | 8 |

| HPG30200 | 2″ | 175 PSIG at 500°F | 3″ | 0.5″ | 6.3 | 117 | 12 |

| HPG30250 | 2.5″ | 175 PSIG at 500°F | 3″ | 0.5″ | 8.8 | 132 | 16 |

| HPG30300 | 3″ | 175 PSIG at 500°F | 3″ | 0.5″ | 13.1 | 161 | 21 |

| HPG30400 | 4″ | 175 PSIG at 500°F | 3″ | 0.5″ | 20.8 | 341 | 28 |

*Joint temperature and pressure ratings depend on the gasket selected by others.