Metraloop® Expansion Joint

Metraloop®

The Metraloop® is called an expansion joint, but it is really much more dynamic than a typical expansion joint. The typical Metraloop® installation is axial for thermal applications, or in any possible direction for seismic applications. And when we say…

Product Description

Product Highlights

Additional Resources

Submittals

Product Description

The Metraloop® is called an expansion joint, but it is really much more dynamic than a typical expansion joint.

The typical Metraloop® installation is axial for thermal applications, or in any possible direction for seismic applications. And when we say any possible direction that includes axial, lateral and angular. Piping systems are used to convey hot water, chilled water, steam, condensate, potable water, fire sprinkler lines, gas lines, waste lines, and the list keeps going. What all these applications have in common is that they all would benefit from a Metraloop®.

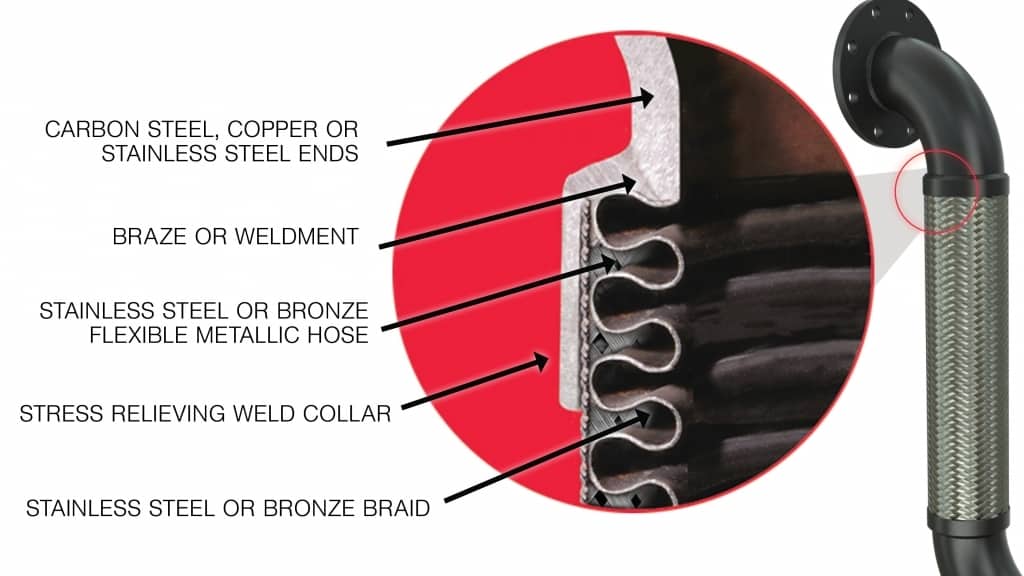

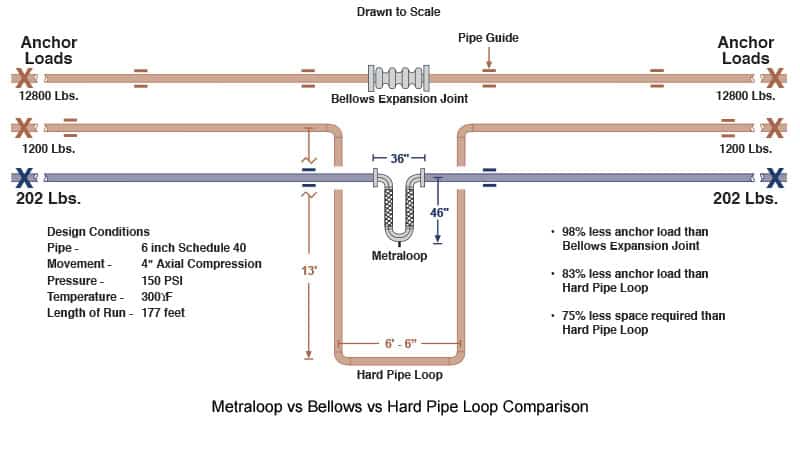

The Metraloop® utilizes the time-tested hose and braid technology, installed perpendicular to the pipeline. Like all the products in the Metraloop® family of products, the Metraloop does not develop thrust loads and this results in almost eliminating the need for guides, simplifying anchor design when compared to in line bellows expansion joints. When you place a Metraloop® in your line, you instantly reduce the stresses in the line.

View Pressure Drop Data

Options

- Liners for high velocity or abrasive material

- Exterior coatings for protection in corrosive environments.

- Double braided for high pressure or steam applications.

- Any fitting that can be welded or brazed to can be used.

- Higher pressure versions available

- Refer to table for temperature and pressure ratings

Product Highlights

- Absorbs both thermal growth and seismic movement in piping systems

- Does not develop thrust loads like in line bellows, resulting in very low anchor loads and guiding requirements.

- It takes up less space and takes less time to install than a hard pipe loop.

- Capable of movement in all directions

- Available in stock and custom configuration up to 84” diameter

- Metraloops can be designed for movements 60” and more.

- The smart solution for all pipe movement requirements.

- UL, FM, UPC, IAPMO and CSA listed models available

- Proudly made in the USA

Additional Resources

Submittals

METRALOOP - STANDARD - SWEAT ENDS

| PIPE SIZE |

MODEL # | MOVEMENT | END TO END |

LENGTH | PSI SINGLE BRAID |

†PSI DOUBLE BRAID |

*SPRING FORCE LBS. |

WEIGHT LBS. |

3D DRAWING |

|---|---|---|---|---|---|---|---|---|---|

| 1/2″ (15mm) | MLS30050 | ±1.5″ | 7-3/4″ | 11-1/2″ | 706 | 1130 | 45 | 2 | Revit/CAD |

| MLS80050 | ±4″ | 7-/34″ | 15-3/8″ | 2.5 | Revit/CAD | ||||

| 3/4″ (20mm) | MLS30075 | ±1.5″ | 9-1/2″ | 13-1/8″ | 577 | 923 | 47 | 2 | Revit/CAD |

| MLS80075 | ±4″ | 9-1/2″ | 17-1/4″ | 2.5 | Revit/CAD | ||||

| 1″ (25mm) | MLS30100 | ±1.5″ | 10-1/4″ | 14-5/8″ | 470 | 752 | 53 | 2.5 | Revit/CAD |

| MLS80100 | ±4″ | 10-1/4″ | 19-1/4″ | 3 | Revit/CAD | ||||

| 1-1/4″ (30mm) | MLS30125 | ±1.5″ | 11-1/8″ | 16-3/8″ | 361 | 577 | 66 | 3.5 | Revit/CAD |

| MLS80125 | ±4″ | 11-1/8″ | 21-3/8″ | 4 | Revit/CAD | ||||

| 1-1/2″ (40mm) | MLS30150 | ±1.5″ | 11-5/8″ | 17-1/4″ | 329 | 526 | 70 | 4 | Revit/CAD |

| MLS80150 | ±4″ | 11-5/8″ | 22-1/2″ | 4.5 | Revit/CAD | ||||

| 2″ (50mm) | MLS30200 | ±1.5″ | 13-3/8″ | 18-3/4″ | 317 | 507 | 78 | 9 | Revit/CAD |

| MLS80200 | ±4″ | 13-3/8″ | 24-3/4″ | 12 | Revit/CAD | ||||

| 2-1/2″ (65mm) | MLS30250 | ±1.5″ | 15″ | 19-3/4″ | 272 | 435 | 83 | 12 | Revit/CAD |

| MLS80250 | ±4″ | 17″ | 26-1/2″ | 18 | Revit/CAD | ||||

| 3″ (80mm) | MLS30300 | ±1.5″ | 16″ | 21-1/2″ | 201 | 322 | 90 | 18 | Revit/CAD |

| MLS80300 | ±4″ | 18-1/2″ | 28-1/2″ | 24 | Revit/CAD | ||||

| 4″ (100mm) | MLS30400 | ±1.5″ | 20″ | 24-3/4″ | 142 | 227 | 120 | 26 | Revit/CAD |

| MLS80400 | ±4″ | 22″ | 32″ | 31 | Revit/CAD |

† When ordering a Metraloop with double-braid, please include the letter “D” at the end of the Model #. Example: MLW30200D

* Spring Force: These values reflect the total force required to move the Metraloop its full rated movement for 150 P.S.I. at 70 F.

For higher pressures please contact Metraflex.

** Loops are available in half sections for ease of handling and shipping. If this option is selected add half inch to the “end to end” dimension.

METRALOOP - STANDARD - THREAD ENDS

| PIPE SIZE |

MODEL # | MOVEMENT | END TO END |

LENGTH | PSI SINGLE BRAID |

†PSI DOUBLE BRAID |

MAX SATURATED STEAM PRESS. |

*SPRING FORCE LBS. |

WEIGHT LBS. |

3D DRAWING |

|---|---|---|---|---|---|---|---|---|---|---|

| 1/2″ (15mm) | MLT30050 | ±1.5″ | 12″ | 10-1/4″ | 1075 | 1720 | 300 | 45 | 3 | Revit/CAD |

| MLT80050 | ±4″ | 15″ | 15-5/8″ | 5.5 | Revit/CAD | |||||

| 3/4″ (20mm) | MLT30075 | ±1.5″ | 12-1/4″ | 10-3/4″ | 792 | 1267 | 300 | 47 | 3 | Revit/CAD |

| MLT80075 | ±4″ | 15-1/4″ | 17-1/2″ | 5.5 | Revit/CAD | |||||

| 1″ (25mm) | MLT30100 | ±1.5″ | 12″ | 12″ | 571 | 914 | 300 | 53 | 5 | Revit/CAD |

| MLT80100 | ±4″ | 16″ | 18-5/8″ | 8 | Revit/CAD | |||||

| 1-1/4″ (30mm) | MLT30125 | ±1.5″ | 13-1/2″ | 13-3/8″ | 531 | 850 | 300 | 66 | 7 | Revit/CAD |

| MLT80125 | ±4″ | 16-3/4″ | 20″ | 10 | Revit/CAD | |||||

| 1-1/2″ (40mm) | MLT30150 | ±1.5″ | 15″ | 14-3/4″ | 472 | 755 | 300 | 70 | 10.5 | Revit/CAD |

| MLT80150 | ±4″ | 17-1/2″ | 21-1/4″ | 14.5 | Revit/CAD | |||||

| 2″ (50mm) | MLT30200 | ±1.5″ | 18″ | 17-3/8″ | 500 | 750 | 300 | 78 | 15 | Revit/CAD |

| MLT80200 | ±4″ | 20″ | 24/1/2″ | 18 | Revit/CAD | |||||

| 2-1/2″ (65mm) | MLT30250 | ±1.5″ | 21″ | 21″ | 387 | 619 | 300 | 83 | 23 | Revit/CAD |

| MLT80250 | ±4″ | 21-1/2″ | 28-1/4″ | 29 | Revit/CAD | |||||

| 3″ (80mm) | MLT30300 | ±1.5″ | 26″ | 23-3/8″ | 288 | 431 | 216 | 90 | 39 | Revit/CAD |

| MLT80300 | ±4″ | 26″ | 30″ | 43 | Revit/CAD | |||||

| 4″ (100mm) | MLT30400 | ±1.5″ | 32″ | 28″ | 232 | 371 | 186 | 120 | 55 | Revit/CAD |

| MLT80400 | ±4″ | 32″ | 35-3/8″ | 59 | Revit/CAD |

† When ordering a Metraloop with double-braid, please include the letter “D” at the end of the Model #. Example: MLW30200D

* Spring Force: These values reflect the total force required to move the Metraloop its full rated movement for 150 P.S.I. at 70 F.

For higher pressures please contact Metraflex.

** Loops are available in half sections for ease of handling and shipping. If this option is selected add half inch to the “end to end” dimension.

METRALOOP - STANDARD - 150# FLANGED ENDS

| PIPE SIZE |

MODEL # | MOVEMENT | END TO END |

LENGTH | PSI SINGLE BRAID |

†PSI DOUBLE BRAID |

MAX SATURATED STEAM PRESS. |

*SPRING FORCE LBS. |

WEIGHT LBS. |

3D DRAWING |

|---|---|---|---|---|---|---|---|---|---|---|

| 2″ (50mm) | MLF30200 | ±1.5″ | 12-1/2″ | 17-3/8″ | 285 | 285 | 300 | 78 | 21 | Revit/CAD |

| MLF80200 | ±4″ | 14-1/2″ | 24-1/2″ | 24 | Revit/CAD | |||||

| 2-1/2″ (65mm) | MLF30250 | ±1.5″ | 15-1/2″ | 21″ | 285 | 258 | 300 | 83 | 30 | Revit/CAD |

| MLF80250 | ±4″ | 16″ | 28-1/4″ | 36 | Revit/CAD | |||||

| 3″ (80mm) | MLF30300 | ±1.5″ | 18-1/2″ | 23-3/8″ | 285 | 285 | 216 | 90 | 46 | Revit/CAD |

| MLF80300 | ±4″ | 18-1/2″ | 30″ | 50 | Revit/CAD | |||||

| 4″ (100mm) | MLF30400 | ±1.5″ | 24-1/2″ | 28″ | 232 | 285 | 183 | 120 | 63 | Revit/CAD |

| MLF80400 | ±4″ | 24-1/2″ | 35-3/8″ | 69 | Revit/CAD | |||||

| 5″ (125mm) | MLF30500 | ±1.5″ | 30-1/2″ | 32-1/4″ | 191 | 285 | 153 | 186 | 91 | Revit/CAD |

| MLF80500 | ±4″ | 30-1/2″ | 40-1/4″ | 101 | Revit/CAD | |||||

| 6″ (150mm) | MLF30600 | ±1.5″ | 36-1/2″ | 36-3/4″ | 165 | 264 | 132 | 202 | 148 | Revit/CAD |

| MLF80600 | ±4″ | 36-1/2″ | 45-3/8″ | 163 | Revit/CAD | |||||

| 8″ (200mm) | MLF30800 | ±1.5″ | 48-1/2″ | 44-1/2″ | 212 | 230 | 115 | 260 | 287 | Revit/CAD |

| MLF80800 | ±4″ | 48-1/2″ | 53-1/2″ | 309 | Revit/CAD | |||||

| 10″ (250mm) | MLF31000 | ±1.5″ | 60-1/2″ | 53-1/4″ | 175 | 200 | 100 | 283 | 453 | Revit/CAD |

| MLF81000 | ±4″ | 60-1/2″ | 63-1/4″ | 484 | Revit/CAD | |||||

| 12″ (300mm) | MLF31200 | ±1.5″ | 72-1/2″ | 61-3/4″ | 160 | 188 | 94 | 390 | 636 | Revit/CAD |

| MLF81200 | ±4″ | 72-1/2″ | 72-3/4″ | 666 | Revit/CAD | |||||

| 14″ (355mm) | MLF31400 | ±1.5″ | 84-1/2″ | 71″ | 110 | 125 | 63 | 706 | 636 | Revit/CAD |

| MLF81400 | ±4″ | 84-1/2″ | 80.5″ | 666 | Revit/CAD | |||||

| 16″ ** (400mm) | MLF31600 | ±1.5″ | 96-1/2″ | 78.5″ | 110 | 170 | 85 | 900 | 636 | Revit/CAD |

| MLF81600 | ±4″ | 96-1/2″ | 91.5″ | 666 | Revit/CAD | |||||

| 18″ ** (455mm) | MLF31800 | ±1.5″ | 108-1/2″ | 86.5″ | 85 | 150 | 75 | 1000 | 636 | Revit/CAD |

| MLF81800 | ±4″ | 108-1/2″ | 100″ | 666 | Revit/CAD |

† When ordering a Metraloop with double-braid, please include the letter “D” at the end of the Model #. Example: MLW30200D

* Spring Force: These values reflect the total force required to move the Metraloop its full rated movement for 150 P.S.I. at 70 F.

For higher pressures please contact Metraflex.

** Loops are available in half sections for ease of handling and shipping. If this option is selected add half inch to the “end to end” dimension.

METRALOOP - STANDARD - WELD ENDS

| PIPE SIZE |

MODEL # | MOVEMENT | END TO END |

LENGTH | PSI SINGLE BRAID |

†PSI DOUBLE BRAID |

MAX SATURATED STEAM PRESS. |

*SPRING FORCE LBS. |

WEIGHT LBS. |

3D DRAWING |

|---|---|---|---|---|---|---|---|---|---|---|

| 1/2″ (15mm) | MLW30050 | ±1.5″ | 6″ | 10-1/4″ | 1075 | 1720 | 300 | 45 | 2.5 | Revit/CAD |

| MLW80050 | ±4″ | 9″ | 15-5/8″ | 5 | Revit/CAD | |||||

| 3/4″ (20mm) | MLW30075 | ±1.5″ | 5-1/4″ | 10-3/4″ | 792 | 1267 | 300 | 47 | 2.5 | Revit/CAD |

| MLW80075 | ±4″ | 9-1/4″ | 17-1/2″ | 5 | Revit/CAD | |||||

| 1″ (25mm) | MLW30100 | ±1.5″ | 6″ | 12″ | 571 | 914 | 300 | 53 | 4 | Revit/CAD |

| MLW80100 | ±4″ | 10″ | 18-5/8″ | 7 | Revit/CAD | |||||

| 1-1/4″ (30mm) | MLW30125 | ±1.5″ | 7-1/2″ | 13-3/8″ | 531 | 850 | 300 | 66 | 6 | Revit/CAD |

| MLW80125 | ±4″ | 10-3/4″ | 20″ | 9 | Revit/CAD | |||||

| 1-1/2″ (40mm) | MLW30150 | ±1.5″ | 9″ | 14-3/4″ | 472 | 755 | 300 | 70 | 9 | Revit/CAD |

| MLW80150 | ±4″ | 11-1/2″ | 21-1/4″ | 13 | Revit/CAD | |||||

| 2″ (50mm) | MLW30200 | ±1.5″ | 12″ | 17-3/8″ | 500 | 750 | 300 | 78 | 13 | Revit/CAD |

| MLW80200 | ±4″ | 14″ | 24-1/2″ | 16 | Revit/CAD | |||||

| 2-1/2″ (65mm) | MLW30250 | ±1.5″ | 15″ | 21″ | 387 | 619 | 300 | 83 | 20 | Revit/CAD |

| MLW80250 | ±4″ | 15-1/2″ | 28-1/4″ | 26 | Revit/CAD | |||||

| 3″ (80mm) | MLW30300 | ±1.5″ | 18″ | 23-3/8″ | 288 | 431 | 216 | 90 | 35 | Revit/CAD |

| MLW80300 | ±4″ | 18″ | 30″ | 39 | Revit/CAD | |||||

| 4″ (100mm) | MLW30400 | ±1.5″ | 24″ | 28″ | 232 | 371 | 186 | 120 | 48 | Revit/CAD |

| MLW80400 | ±4″ | 24″ | 35-3/8″ | 54 | Revit/CAD | |||||

| 5″ (125mm) | MLW30500 | ±1.5″ | 30″ | 32-1/4″ | 191 | 306 | 153 | 186 | 81 | Revit/CAD |

| MLW80500 | ±4″ | 30″ | 40-1/4″ | 91 | Revit/CAD | |||||

| 6″ (150mm) | MLW30600 | ±1.5″ | 36″ | 36-3/4″ | 165 | 264 | 132 | 202 | 125 | Revit/CAD |

| MLW80600 | ±4″ | 36″ | 45-3/8″ | 140 | Revit/CAD | |||||

| 8″ (200mm) | MLW30800 | ±1.5″ | 48″ | 44-1/2″ | 212 | 230 | 115 | 260 | 245 | Revit/CAD |

| MLW80800 | ±4″ | 48″ | 53-1/2″ | 267 | Revit/CAD | |||||

| 10″ (250mm) | MLW31000 | ±1.5″ | 60″ | 53-1/4″ | 175 | 200 | 100 | 383 | 403 | Revit/CAD |

| MLW81000 | ±4″ | 60″ | 63-1/4″ | 434 | Revit/CAD | |||||

| 12″ (300mm) | MLW31200 | ±1.5″ | 72″ | 61-3/4″ | 160 | 188 | 94 | 390 | 556 | Revit/CAD |

| MLW81200 | ±4″ | 72″ | 72-3/4″ | 586 | Revit/CAD |

† When ordering a Metraloop with double-braid, please include the letter “D” at the end of the Model #. Example: MLW30200D

* Spring Force: These values reflect the total force required to move the Metraloop its full rated movement for 150 P.S.I. at 70 F.

For higher pressures please contact Metraflex.

** Loops are available in half sections for ease of handling and shipping. If this option is selected add half inch to the “end to end” dimension.

METRALOOP - STANDARD - GROOVED ENDS

| PIPE SIZE |

MODEL # | MOVEMENT | FACE TO FACE |

LENGTH | PSI SINGLE BRAID |

†PSI DOUBLE BRAID |

*SPRING FORCE LBS. |

WEIGHT LBS. |

3D DRAWING |

|---|---|---|---|---|---|---|---|---|---|

| 2″ (50mm) | MLG30200 | ±1.5″ | 18″ | 17-3/8″ | 500 | 750 | 78 | 15 | Revit/CAD |

| MLG80200 | ±4″ | 20″ | 24-1/2″ | 18 | Revit/CAD | ||||

| 2-1/2″ (65mm) | MLG30250 | ±1.5″ | 21″ | 21″ | 387 | 619 | 83 | 23 | Revit/CAD |

| MLG80250 | ±4″ | 21-1/2″ | 28-1/4″ | 29 | Revit/CAD | ||||

| 3″ (80mm) | MLG30300 | ±1.5″ | 24″ | 23-3/8″ | 288 | 431 | 90 | 39 | Revit/CAD |

| MLG80300 | ±4″ | 24″ | 30″ | 43 | Revit/CAD | ||||

| 4″ (100mm) | MLG30400 | ±1.5″ | 30″ | 28″ | 232 | 371 | 120 | 54 | Revit/CAD |

| MLG80400 | ±4″ | 30″ | 35-3/8″ | 60 | Revit/CAD | ||||

| 5″ (125mm) | MLG30500 | ±1.5″ | 36″ | 32-1/4″ | 191 | 306 | 186 | 89 | Revit/CAD |

| MLG80500 | ±4″ | 36″ | 40-1/4″ | 99 | Revit/CAD | ||||

| 6″ (150mm) | MLG30600 | ±1.5″ | 42″ | 36-3/4″ | 165 | 264 | 202 | 135 | Revit/CAD |

| MLG80600 | ±4″ | 42″ | 45-3/8″ | 150 | Revit/CAD | ||||

| 8″ (200mm) | MLG30800 | ±1.5″ | 56″ | 44-1/2″ | 212 | 230 | 260 | 264 | Revit/CAD |

| MLG80800 | ±4″ | 56″ | 53-1/2″ | 286 | Revit/CAD | ||||

| 10″ (250mm) | MLG31000 | ±1.5″ | 68″ | 53-1/4″ | 175 | 200 | 283 | 430 | Revit/CAD |

| MLG81000 | ±4″ | 68″ | 63-1/4″ | 461 | Revit/CAD | ||||

| 12″ (300mm) | MLG31200 | ±1.5″ | 80″ | 61-3/4″ | 160 | 188 | 390 | 592 | Revit/CAD |

| MLG81200 | ±4″ | 80″ | 72-3/4″ | 622 | Revit/CAD |

† When ordering a Metraloop with double-braid, please include the letter “D” at the end of the Model #. Example: MLW30200D

* Spring Force: These values reflect the total force required to move the Metraloop its full rated movement for 150 P.S.I. at 70 F.

For higher pressures please contact Metraflex.

** Loops are available in half sections for ease of handling and shipping. If this option is selected add half inch to the “end to end” dimension.